ACU is now offering 5-Axis Waterjet Cutting. This machine uses a high-pressure jet of water and abrasive substance to cut through our plastic materials. The Waterjet is capable of cutting intricate parts to print that are not possible on other machining equipment.

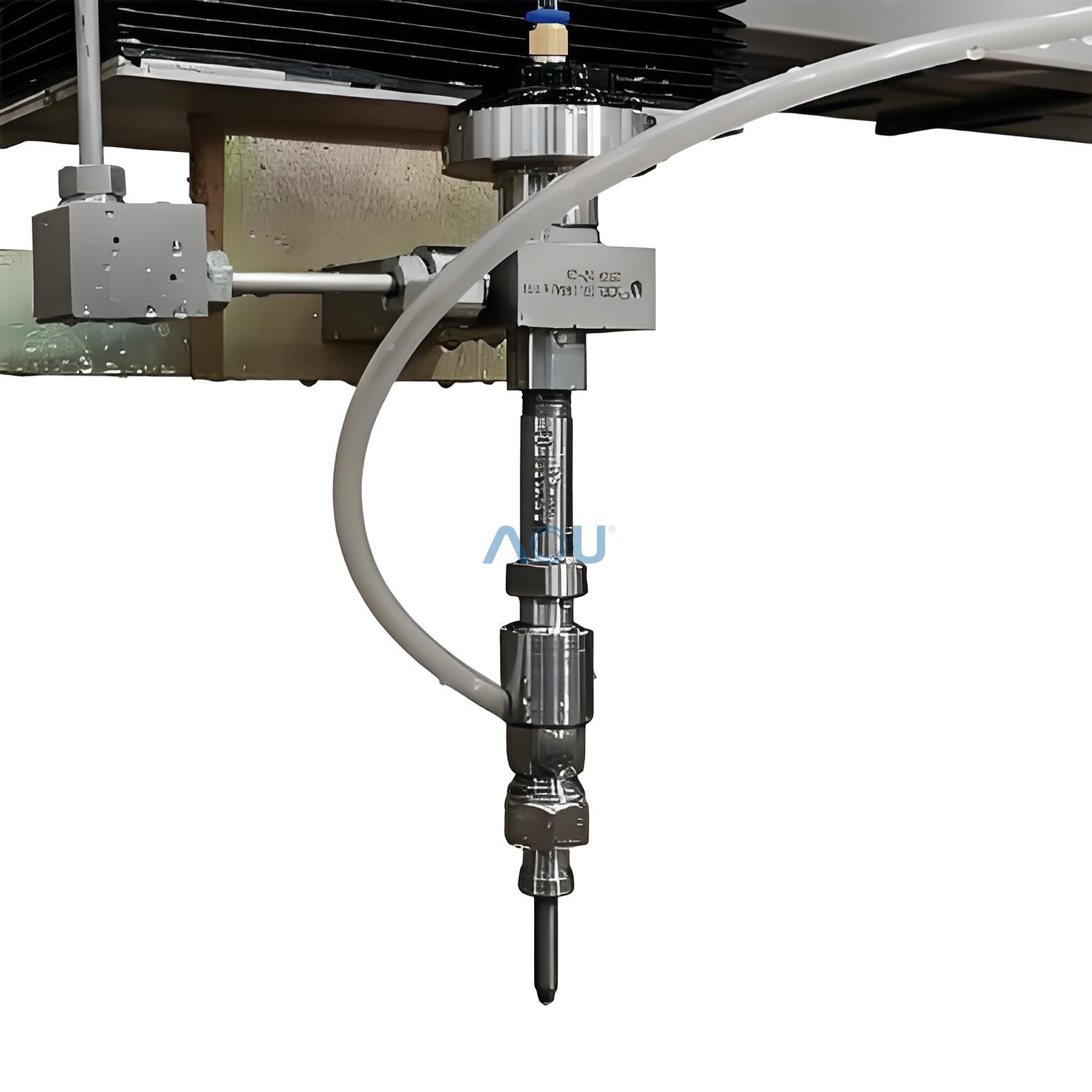

Cutting Head

1. Water Jet Cutting Head: Three-axis cutting head

2. Advantages: Simple operation, compact structure, easy to operate and maintain

3. Features: The cutting head can automatically return to the reference point during cutting, and automatically lift after cutting is completed. The sand valve is positioned at the front (on the same side as the cutting head's sandblasting pipe, facilitating maintenance).

Cutting Platform 2515

1. Structure: Gantry-style integrated beam structure

2. Cutting Platform Size: 2600*1600mm

3. Cutting Stroke: X-2400mm, Y-1500mm, Z-60~80mm

4. Cutting Accuracy: ±0.1mm

5. Repeatability: ±0.05mm

6. Oil-immersed ball screw guide rail beam structure.

Intensifier Unit

1. Boosted Drive Mode: Hydraulic drive

2. Main Motor Power: 37kW

3. Maximum Relief Pressure: 450MPa

4. Normal Operating Pressure: 290-310MPa

5. Power Supply: 380V, 50Hz (customizable)

6. Cooling Method: Oil circulation with air conditioning cooling

7. Accumulator: Imported high-pressure materials from Taiwan

8. Human-Machine Interface: The booster interface displays alarm prompts, such as water leakage, pressure abnormalities, overheating, maintenance reminders, and self-diagnostics for various issues.

CNC Controller CNC

1. 21.5-inch Display

2. IWCUT Cutting Software

3. File Transfer: Can be connected via TCP/IP network or USB port

4. Compatible Software: CAD/CAM software for specialized water jet cutting machines

5. Servo Drive Brand: INOVANCE

Abrasive Feeding System

1. Pneumatic Sand Supply System: No high-pressure electricity required, safe and reliable.

2. Maximum Water Jet Abrasive Capacity: 200kg.

Main technical data

|

Processing speed |

0.5~3.5 m/min(depending on cut material ) |

|

Max no-load moving speed |

15m/min |

|

Installed Power |

40KW |

|

Water inlet pressure |

0.2 ~ 0.4 Mpa |

|

Maximum water discharge ratio |

3.7 L/min |

|

Oil recycling discharge ratio |

10 ~ 71 L/min |

|

Water compression ratio |

20:1 |

|

Diamond orifice size |

0.33 mm |

Processing thickness: (Max. thickness for example)

|

Material |

Glass |

Ceramics |

Marble |

Steel |

Aluminum Alloy |

Rock Board |

|

Thickness |

120mm |

80mm |

100mm |

80mm |

150mm |

30mm |

ACU-450B Intensifier Unit ACU-450

|

Intensifier Parts |

|

|

Tank body |

Foshan ACU |

|

Piston |

Imported |

|

Seal parts |

Imported from America |

|

High-pressure Cylinder |

Imported from America |

|

Ceramic plunger (ceramic rod) |

Imported |

|

High pressure seal |

Imported |

|

Water inlet valve |

Imported |

|

Accumulator |

Foshan ACU |

|

Oil pump type |

Plunger pump |

|

Maximum oil pump pressure |

31.5 MPa |

|

Main motor power |

37kW |

|

Oil tank volume |

70L |

|

Proportional Valve |

HUADE |

|

Liquid Electricity reverse valve |

America HYTEK |

|

CNC controlling system software |

IWCUT |

|

CNC computer softwar |

Auto CAD |

|

High-pressure water on/off switch structure |

Pneumatic switch |

|

X, Y, Z axis motor and driver supplier |

INOVANCE |

|

Water pump |

Imported from Italy |

|

Track |

Imported |

|

Ball screw |

Imported |

|

Attchment 1:Free Spare Parts of Waterjet (for ACU-450 type intensifier pump box) |

|||

|

Seq |

Description |

Spec |

Qty |

|

01 |

Diamond orifice |

0.33mm |

4 |

|

02 |

Abrasive Mixing Tube Collet |

7.14 |

2 |

|

03 |

Abrasive Mixing Tube |

7.14 |

1 |

|

04 |

Spray Shield |

|

2 |

|

05 |

Abrasive Mixing Tube Fixing Nut |

|

2 |

|

06 |

Nozzle Body for 3-axis head |

7.14 |

1 |

|

07 |

On/off switch valve pad |

|

2 |

|

08 |

On/off switch seal group |

|

2 |

|

09 |

Door nut (I) |

|

2 |

|

10 |

Door nut (II) |

|

2 |

|

11 |

HP tube collar (I) |

|

2 |

|

12 |

HP tube collar (Ⅱ) |

|

2 |

|

13 |

On/off switch adapter valve pad |

|

2 |

|

14 |

One-way valve |

|

1 |

|

15 |

One-way valve pad, poppet and spring |

Suitable for 1/2 high pressure pipe |

2 |

|

16 |

Inlet Valve Fixing Nut |

|

2 |

|

19 |

High-pressure seal kit |

|

2 |

|

20 |

Shift Sensor Spring |

|

2 |

|

21 |

Shift Sensor Actuator Assembly |

|

2 |

|

22 |

Tool Box |

|

1 |

|

23 |

320 sand paper |

|

5 |

|

24 |

1000 sand paper |

|

5 |

|

25 |

2000 sand paper |

|

5 |

|

26 |

Sand paper |

|

5 |

|

27 |

On/off switch disassembling tool |

- |

1 |

|

28 |

High-pressure seal kit disassembling tool |

- |

1 |

|

29 |

High-pressure cylinder disassembling spanner |

- |

1 |

|

30 |

Crescent Wrench |

- |

1 |

|

31 |

Spanner |

- |

1 |

|

32 |

Cross screwdriver |

|

1 |

|

33 |

Slotted Screwdriver |

|

1 |

|

34 |

Cap screwdriver |

|

1 |

|

35 |

Cap screwdriver |

|

1 |

|

36 |

Dial indication |

|

1 |

|

37 |

Flat-nose Pliers |

|

1 |

|

38 |

Blue Goop |

|

1 |

|

39 |

Electricity drawing |

0 |

1 |

|

40 |

Horizontal Ruler |

|

1 |

|

41 |

Garnet Abrasive mesh#80 |

Mesh 80# |

500 kg |

|

42 |

USB storage disk |

|

1 pc |

|

43 |

Screw |

5*10 |

20 pcs |

|

44 |

Screw |

6*10 |

20 pcs |

|

45 |

3-way connector for air compressor outlet |

8cm |

2 |

|

46 |

Catalog for spare parts |

|

2 |

|

47 |

Keyboard & Mouse |

|

1 |

|

48 |

250mm *ø8 * 4, 500mm *ø8 * 1 |

|

5 |

|

49 |

M12 inner hexagon wrench M12 |

|

1 |

Our hours

Mon 11/21 - Wed 11/23: 9 AM - 8 PM

Thu 11/24: closed - Happy Thanksgiving!

Fri 11/25: 8 AM - 10 PM

Sat 11/26 - Sun 11/27: 10 AM - 9 PM

(all hours are Eastern Time)